- +86 189 6522 2690

- [email protected]

- NO.36 DAPU ROAD, FENGNAN , | XIAMEN

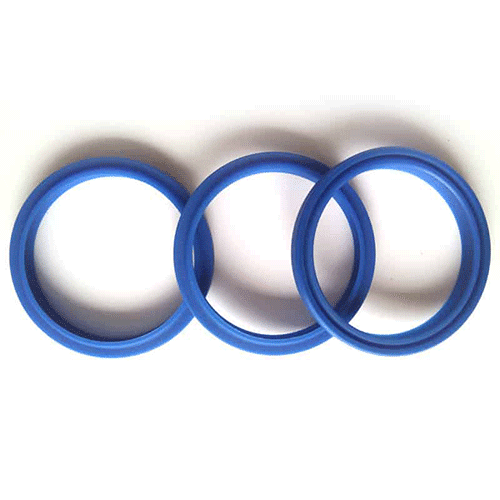

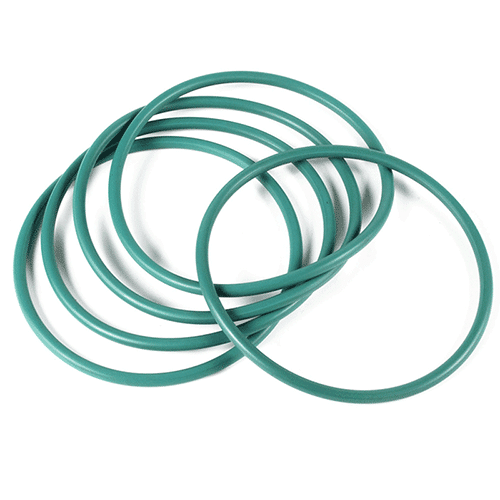

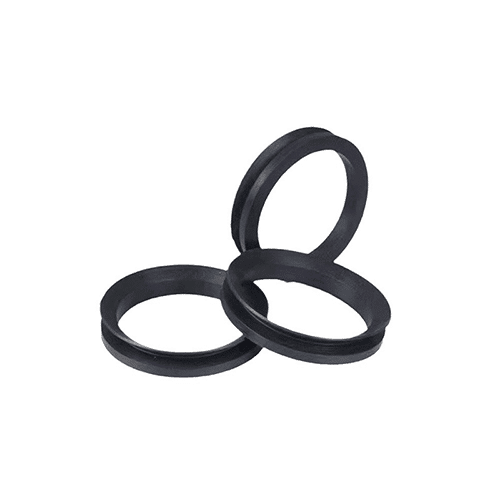

We manufacture a wide variety of rubber O rings to address different sealing needs:

Off-the-shelf solutions that meet industry-standard dimensions and performance criteria for general applications.

Engineered for extreme conditions, including high-pressure, high-temperature, or chemically aggressive environments.

Designed to reduce friction in dynamic applications, ensuring smooth motion and longevity in moving components.

Tailored to unique specs, dimensions, and performance needs for specialized applications.

Not seeing the exact O-ring you need? Let our sealing experts assist you!

Our diverse material portfolio allows us to offer O rings that excel in various applications:

Excellent weather, UV, and ozone resistance. Ideal for outdoor and automotive applications.

Superior oil, fuel, and solvent resistance. Ideal for automotive and industrial machinery.

Outstanding wear and impact resistance. Ideal for heavy-duty industrial applications.

High-performance thermoplastic with excellent chemical, wear, and heat resistance.

Combines the benefits of silicone and fluorocarbon for high resistance to chemicals and fuels.

Best-in-class chemical and high-temperature resistance. Performs well under high-pressure environments.

Cost-effective with decent abrasion and wear resistance. Ideal for general-purpose applications.

Excellent flexibility and performance in extreme temperatures (-100°F to +500°F). Non-reactive, FDA compliant.

Superior resistance to high temperatures (up to 250°C) and harsh chemicals. Ideal for aerospace and industrial.

Good resistance to wear, aging, and moderate chemicals. Performs in a wide temperature range.

Selecting the right manufacturer is critical for ensuring that your rubber O ring perform optimally in your application. Here’s why we stand out:

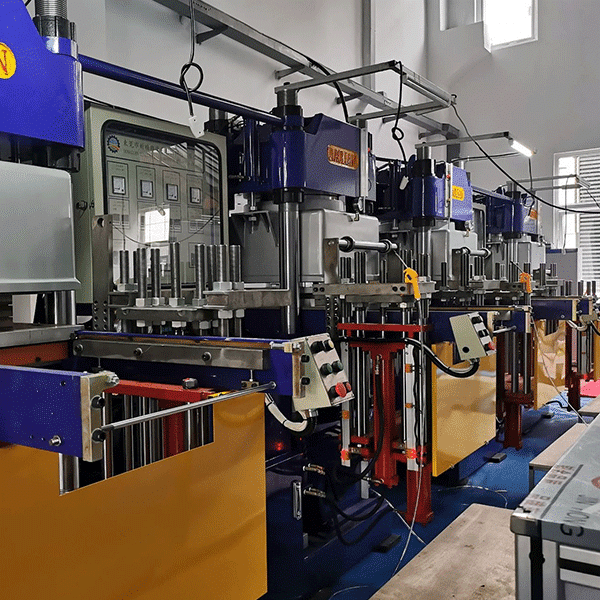

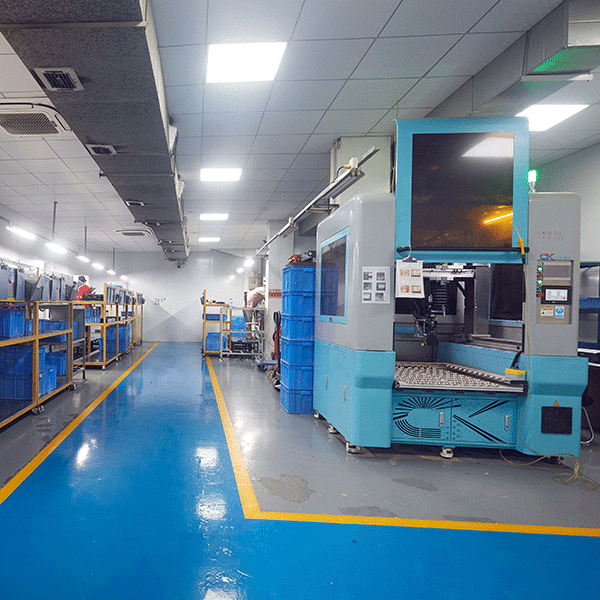

With over 15 years of expertise, YI FENG RUBBER CO., LTD is a leading manufacturer of high-quality rubber seals in China. Our state-of-the-art facility is equipped with 36 vulcanizing machines, including 14 vacuum vulcanizing machines and 22 curing presses, with specifications ranging from 400 mm to 2,000 mm.

We specialize in providing customized rubber solutions using a wide range of materials, such as NBR, FKM, and EPDM, in any color to suit your needs. Our extensive inventory includes 7,000+ mold sets that cover American, European, and Japanese standards, ensuring we can meet nearly every market demand.

Learn more about our services and solutions.

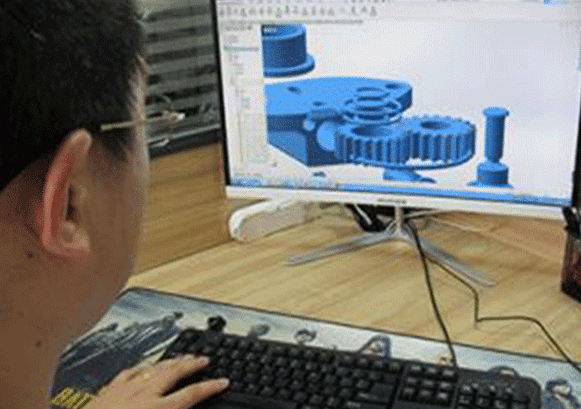

Have an idea? Just let us know! Share your design, sketch, or even just your vision. We're here to listen and help you bring your product to life.

Once we understand your needs, our expert team takes over. We'll use our skills and technology to manufacture your custom rubber products with precision and care.

We don't just make it; we make it right! Every product is carefully checked for quality before being securely packed and prepared for its journey to you.

The final step is the shipment of your completed order directly to your specified location. We work with reliable shipping partners to ensure timely and secure delivery.

Our rubber O ring are trusted across many industries, including:

Gaskets for engines, exhaust systems, and sealing applications.

Gaskets designed to withstand extreme pressures and harsh chemicals.

Sealing solutions for machinery, HVAC, and heavy-duty industrial systems.

Our standard lead time is as short as 8 business days, depending on the complexity and volume of your order.

No, we have no minimum order requirements! Whether you need a single display or a large batch, we can accommodate your needs.

Yes, we can provide material samples upon request to help you make the right selection for your application.

We typically accept DWG, DXF, STEP, and IGES files.

We offer free samples so you can experience the quality of our displays before placing an order. We’re confident you’ll love the results!

+86 189 6522 2690

NO.36 DAPU ROAD,

FENGNAN , | XIAMEN CITY

CHINA