- +86 189 6522 2690

- [email protected]

- NO.36 DAPU ROAD, FENGNAN , | XIAMEN

We use multiple molding and fabrication methods to produce bellows that meet tight tolerances and performance requirements.

High-volume, consistent quality with complex geometry options.

Steel, stainless steel, or brass options provide stable mounting points.

Seamless design with flexible walls—best for dust boots and covers.

Added durability and high-pressure resistance using coated fabrics.

Not seeing the option you’re looking for? Have our sourcing experts assist you!

We provide a wide range of rubber materials to match your chemical, temperature, flexibility, and durability needs.

Provides excellent flexibility, high tensile strength, and abrasion resistance, suitable for various sealing and vibration dampening applications.

Known for its wide temperature range, flexibility, and resistance to weathering and ozone, often used in medical, food-grade, and high-temperature applications.

Offers a good balance of oil, chemical, and weather resistance, commonly used in automotive, industrial, and marine applications.

Renowned for its excellent resistance to weathering, ozone, and UV radiation, making it ideal for outdoor applications and environments with exposure to the elements.

Excellent resistance to oils, fuels, and hydraulic fluids, making it ideal for sealing applications in the automotive and industrial sectors.

Offers superior resistance to high temperatures, chemicals, and oils, making it a top choice for demanding industrial and automotive environments.

YF Rubber is a trusted rubber bellow manufacturer, delivering durable, high-performance rubber bushings and bellows for industrial, automotive, and custom OEM applications. Our bellows are engineered to protect critical components from dust, debris, and environmental factors, extending their lifespan and ensuring optimal performance.

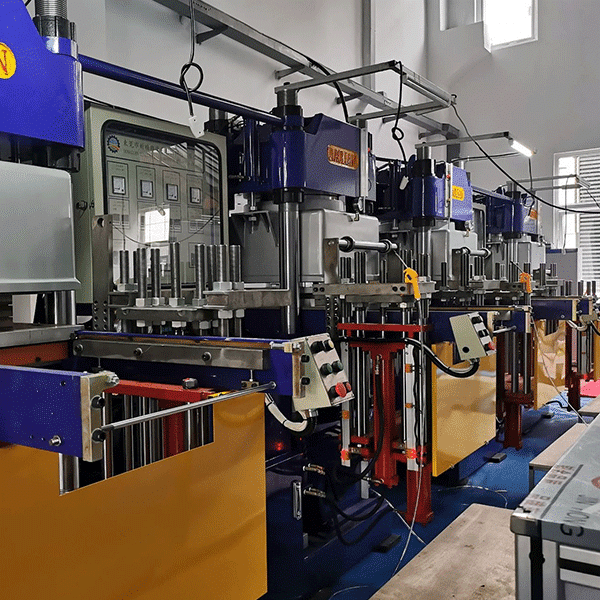

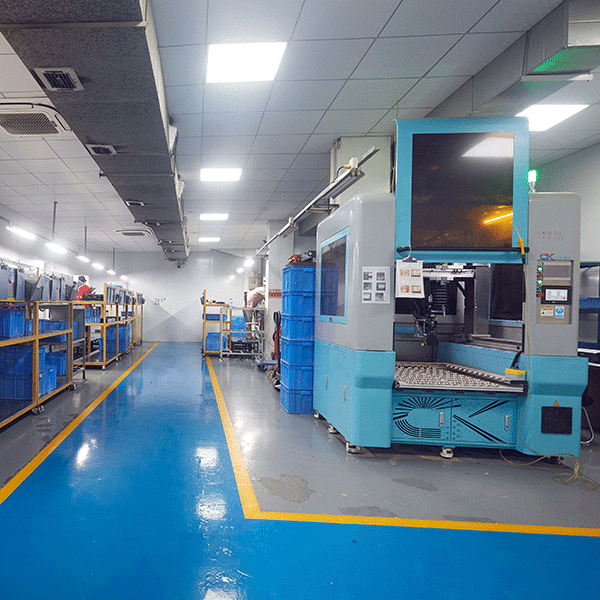

With over 15 years of expertise, YI FENG RUBBER CO., LTD is a leading manufacturer of high-quality rubber seals and bellows in China. Our state-of-the-art facility is equipped with 36 vulcanizing machines, including 14 vacuum vulcanizing machines and 22 curing presses, with specifications ranging from 400 mm to 2,000 mm. We are dedicated to providing exceptional rubber solutions.

We specialize in providing customized rubber solutions using a wide range of materials, such as NBR, FKM, and EPDM, in any color to suit your needs. Our extensive inventory includes 7,000+ mold sets that cover American, European, and Japanese standards, ensuring we can meet nearly every market demand with precision and efficiency.

Learn more about our services and solutions.

YF Rubber stands apart from other rubber bellow manufacturers by combining extensive engineering expertise, advanced tooling capabilities, and responsive customer service. Whether you require standard or fully customized bellows, our team is ready to deliver precise solutions tailored exactly to your specifications.

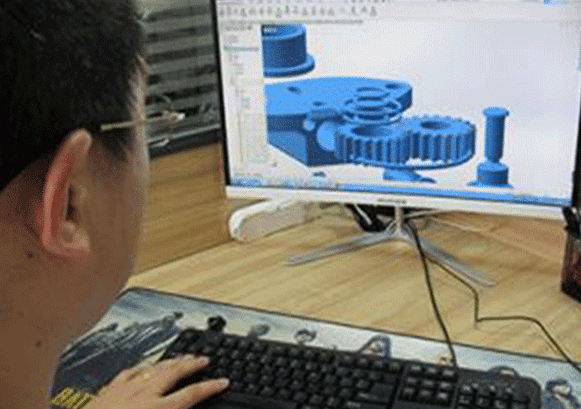

Have an idea? Just let us know! Share your design, sketch, or even just your vision. We're here to listen and help you bring your product to life.

Once we understand your needs, our expert team takes over. We'll use our skills and technology to manufacture your custom rubber products with precision and care.

We don't just make it; we make it right! Every product is carefully checked for quality before being securely packed and prepared for its journey to you.

The final step is the shipment of your completed order directly to your specified location. We work with reliable shipping partners to ensure timely and secure delivery.

Our rubber mountings and bellows are trusted across many industries, including:

Providing essential gaskets for engines, exhaust systems, and various sealing applications, as well as protective bellows for components like CV joints and steering racks.

Manufacturing gaskets and bellows designed to withstand extreme pressures, harsh chemicals, and demanding environmental conditions prevalent in the oil and gas sector.

Delivering critical sealing solutions for a wide range of machinery, HVAC systems, heavy-duty industrial equipment, and robotic applications.

Rubber bellows are flexible connectors used to absorb movement, isolate vibration, and protect components from environmental contaminants. They act as seals and expansion joints between rigid parts—ideal for both static and dynamic applications.

Key Functions:

Compensate for axial, lateral, and angular movement

Absorb mechanical shock and vibration

Act as a barrier against:

Dust

Grease & oil

Water & chemicals

UV & ozone

Prevent mechanical wear on sensitive components

Optional Designs:

Round, oval, rectangular, or custom-shaped bellows

Convoluted bellows with multiple folds

Tapered bellows for tighter assembly

Single, double, or triple cuffed ends for secure mounting

Yes! We support custom geometries with both molded and fabric-reinforced options.

Standard items ship quickly; custom parts are usually ready in 2–4 weeks.

Molded bellows can have more complex shapes and varied thickness; dip-molded parts are seamless and best for uniformity.

We offer free samples so you can experience the quality of our displays before placing an order. We’re confident you’ll love the results!

+86 189 6522 2690

NO.36 DAPU ROAD,

FENGNAN , | XIAMEN CITY

CHINA