- +86 189 6522 2690

- [email protected]

- NO.36 DAPU ROAD, FENGNAN , | XIAMEN

We manufacture a comprehensive variety of rubber bush styles and configurations, including press-fit bushings, meticulously tailored to your drawings or technical requirements. Each component is engineered by your expert rubber bush manufacturer for superior performance and durability:

Precision-molded for flexibility, shock absorption, and longevity.

Steel, stainless steel, or brass options provide stable mounting points.

Designed for press-fit applications, made from steel, brass, or aluminum.

Not seeing the exact configuration you need for your vibration damping bushings? Our sourcing experts are ready to assist!

We utilize a range of high-performance materials selected for durability, temperature resistance, chemical compatibility, and suitability for your specific operating environment. As a leading rubber bush manufacturer, we work with:

Excellent resilience and fatigue resistance.

High flexibility and broad temperature tolerance.

Good resistance to weathering, oils, and abrasion.

Outstanding ozone and UV resistance.

Ideal for fuel- and oil-resistant applications.

YF Rubber is a trusted rubber bush manufacturer delivering durable, high-performance rubber bushings for industrial, automotive, and custom OEM applications. Our bushings are engineered to reduce vibration, isolate noise, and accommodate movement—enhancing the life and efficiency of your equipment.

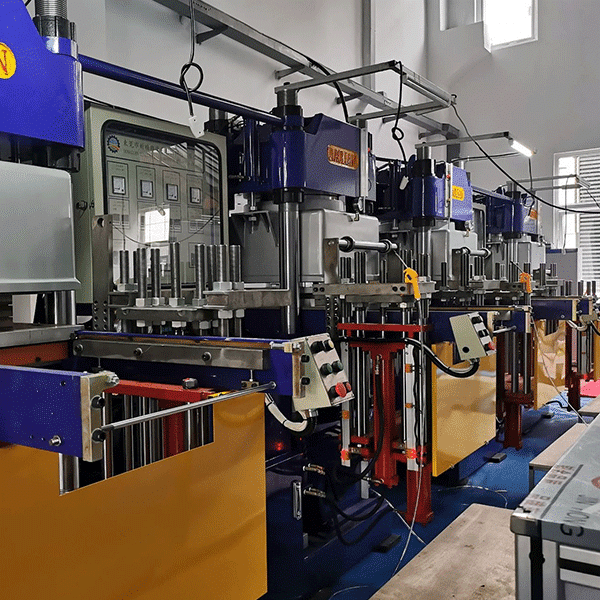

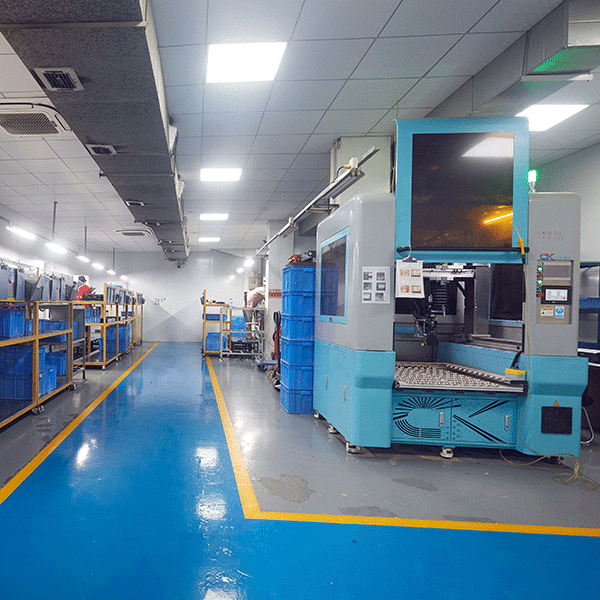

With over 15 years of manufacturing expertise, YF Rubber is a premier producer of high-quality custom rubber components in China. Our state-of-the-art facility houses 57+ advanced machines, including 36 vulcanizing units.

We specialize in customized rubber solutions using materials like NBR, FKM, EPDM, Silicone, and more. Our 7,000+ mold sets cover American, European, and Japanese standards, ensuring we meet market demands for rubber bushings and related parts. We employ 50+ skilled staff in our 6100+ square meter workshops, with a production capacity exceeding 1.2 million pieces monthly.

Learn more about our services and solutions.

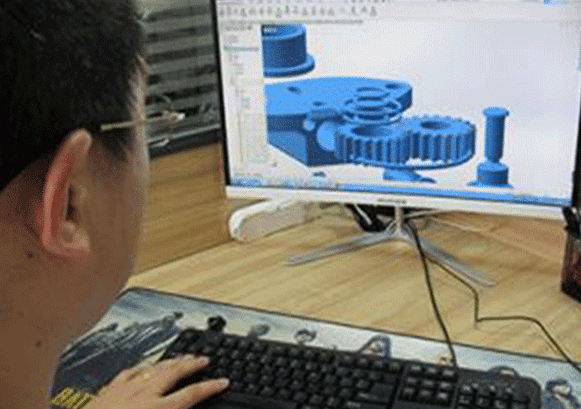

Partnering with YF Rubber means leveraging deep engineering expertise and advanced tooling for your custom rubber parts. Here’s our simple process:

Have an idea? Just let us know! Share your design, sketch, or even just your vision. We're here to listen and help you bring your product to life.

Once we understand your needs, our expert team takes over. We'll use our skills and technology to manufacture your custom rubber products with precision and care.

We don't just make it; we make it right! Every product is carefully checked for quality before being securely packed and prepared for its journey to you.

The final step is the shipment of your completed order directly to your specified location. We work with reliable shipping partners to ensure timely and secure delivery.

Our custom rubber bushings are trusted across diverse sectors:

Gaskets for engines, exhaust systems, and sealing applications.

Gaskets designed to withstand extreme pressures and harsh chemicals.

Sealing solutions for machinery, HVAC, and heavy-duty industrial systems.

A rubber bush (also called a rubber bushing) is a vibration-isolating component typically used to provide a flexible interface between two rigid parts. They reduce noise, absorb shocks, and compensate for misalignment in mechanical systems—commonly found in automotive suspension systems, industrial machines, and equipment linkages.

Yes, we specialize in custom rubber bush manufacturing. You can provide us with your technical drawings, specifications, or even a physical sample, and our in-house engineering team will assist with design optimization and tooling for production.

Our typical MOQ is 1,000 pieces for custom rubber bushings. However, this may vary depending on the design complexity and material requirements. Please contact us to discuss your specific needs.

Custom orders may have 1000pcs MOQ requirements depending on the tooling and materials involved.

Yes, we can provide samples of custom rubber bushings for your testing and approval before proceeding to full production. This ensures the final product meets your performance and dimensional requirements.

We offer free samples so you can experience the quality of our displays before placing an order. We’re confident you’ll love the results!

+86 189 6522 2690

NO.36 DAPU ROAD,

FENGNAN , | XIAMEN CITY

CHINA